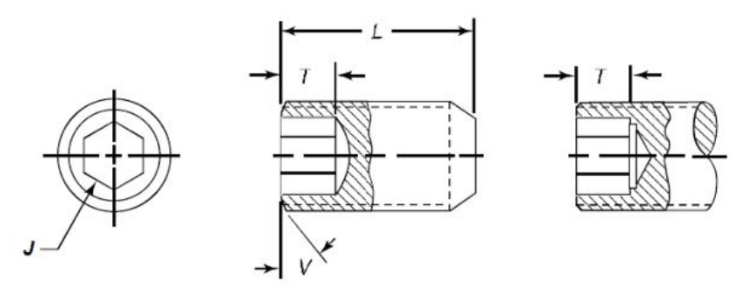

Socket Set Screws

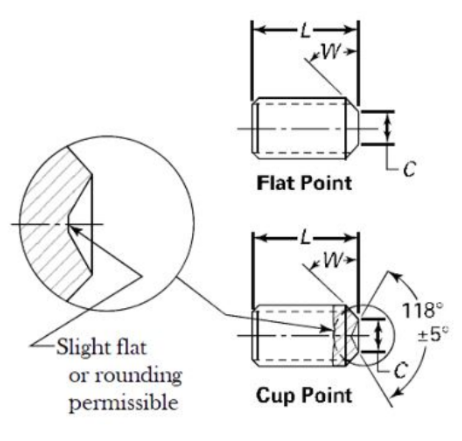

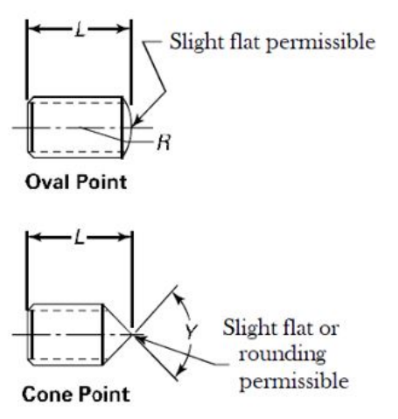

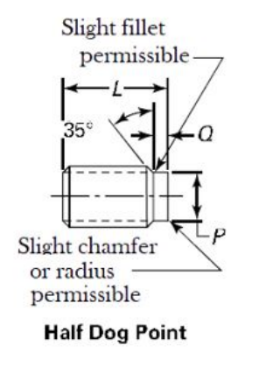

Certain applications require a screw that is buried completely in a tapped hole in one of the material surfaces. This is a job for a socket set screw. An important consideration when choosing a socket set screw is how it will interact with the material at the bottom of the hole. If the set screw is to “dig-in”, a point style which features minimal surface area works best. These point styles would include cup, cone or knurled cup. If minimal marring of the surface is required, flat, full dog or half dog would be the point style of choice. Cup point is the most common style in inventory at Nickel Systems.

REQUEST A QUOTE