Nuts & bolts are fundamental to the fastener world. They provide secure & reliable connections in many applications. Finished hex nuts & heavy hex nuts are two common nuts which are used in structural & mechanical applications. These two types of nuts have unique differences that make each suitable for different applications. In this article, we will explore the unique characteristics of finished hex nuts & heavy hex nuts in order to help you determine which hex nut is best for your next project.

A hex nut is a six-sided, threaded fastener. It is the female mate to a bolt or threaded rod. When joined together, this unit securely fastens components. The nut’s hex shape allows easy access for installation in tight spaces.

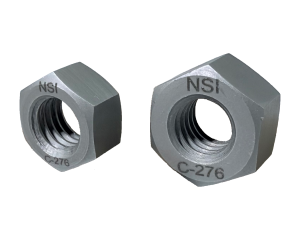

Finished hex nuts are smaller & lighter than heavy hex nuts. They are designed for general-purpose applications.

Heavy hex nuts are larger & thicker than standard hex nuts. They feature a wider across-the-flats dimension. Additionally, their increased thickness provides extra strength & durability.

For applications that require exceptional resistance to extreme conditions, Nickel System’s exotic alloys are an excellent choice. Materials such as Inconel, Monel, & Hastelloy provide excellent strength, corrosion resistance, & temperature tolerance. These alloys are commonly used in industries such as aerospace, marine, & chemical processing.

At Nickel Systems, heavy hex nuts & finished hex nuts are readily available in these exotic materials.

Here are some tips to guide your hex nut selection:

Whether you need heavy hex nuts or finished hex nuts, Nickel Systems offers a comprehensive range of high-quality fasteners to meet your needs. With a commitment to excellence & a diverse inventory, Nickel Systems ensures that you will find the perfect solution for your project.

Visit our Finished Hex Nuts page to explore our range of compact, versatile options.

For robust and reliable fasteners, check out our Heavy Hex Nuts page to find the strength and durability you need.

Understanding the differences between heavy hex nuts & finished hex nuts is essential for selecting the right fastener for your project while meeting your budget requirements. In review heavy hex nuts excel in structural & high-stress scenarios, finished hex nuts offer versatility and ease of use for general-purpose needs. By considering factors such as load requirements, environmental conditions, and material properties, you can make an informed decision that ensures the success & longevity of your project.

For the highest quality hex nuts in a variety of materials, including exotic alloys, trust Nickel Systems to deliver.

Explore our product pages today and find the fasteners you need to complete your project with confidence.

By selecting the fastener fit for your application, installing it properly and performing regular inspections, you greatly increase your chances of seeing long-term performance with minimal issues.

At Nickel Systems, we take pride in providing specialty stainless steel and custom nickel alloy fasteners. With years of industry expertise, our team can select the best option for your purposes while providing you with individualized support. We’re a true stock company and deliver a quick turnaround time on orders.

To explore our stainless steel fastener selection, call us today at 610-632-1964 or complete this online form to get a quote. You can also email us at [email protected].