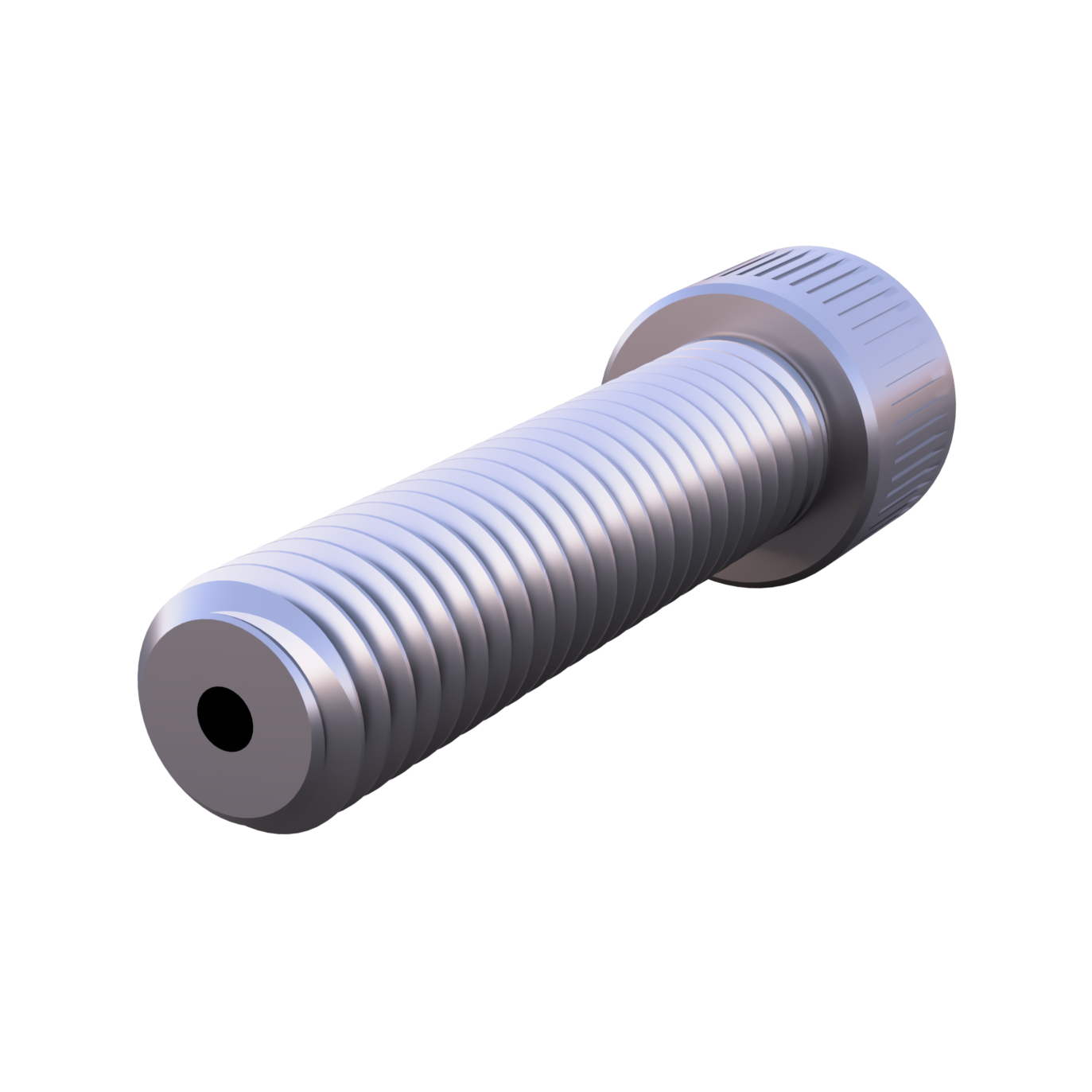

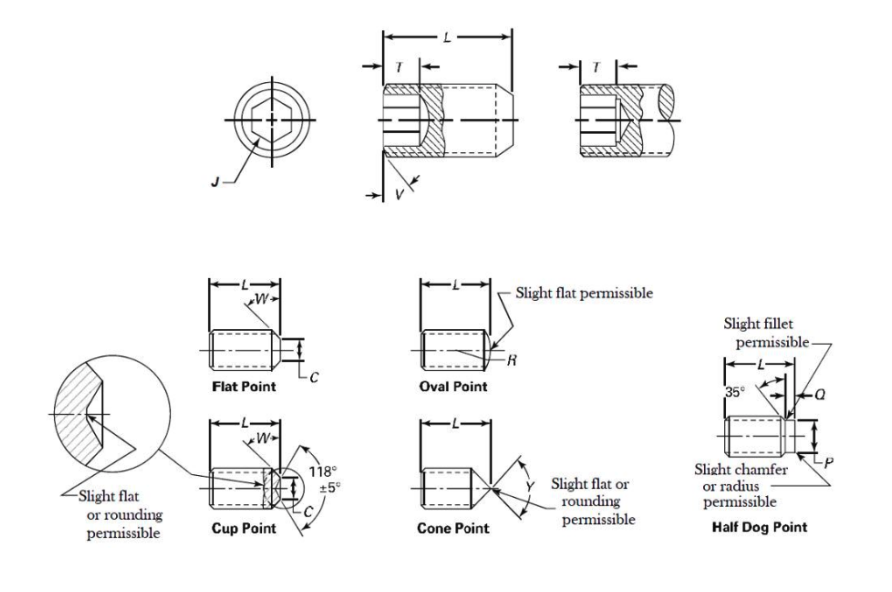

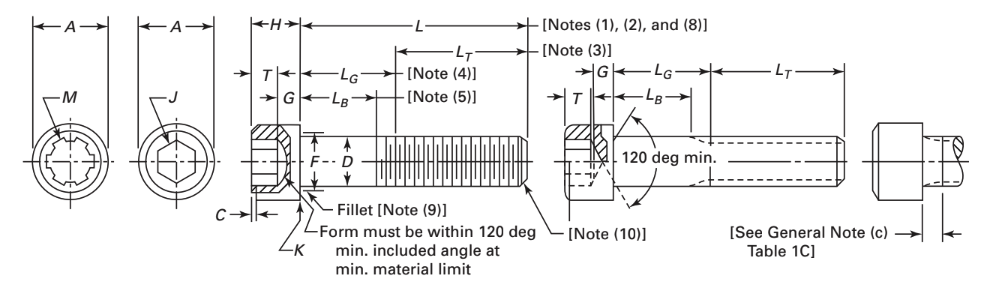

Dimensions

|

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size (Basic Screw Diameter) | Body Diameter, D | Head Diameter, A | Head Height, H | Maximum Chamfer or Radius, C | Nominal Spline Socket Size, M | Nominal Hexagon Socket Size, J | Minimum Key Engagement, T | Minimum Wall Thickness, G | Maximum Chamfer or Radius, K | ||||

| Max | Min | Max | Min | Max | Min | ||||||||

| 0 (0.0600) | 0.0600 | 0.0568 | 0.096 | 0.091 | 0.060 | 0.057 | 0.004 | 0.060 | — | 0.050 | 0.025 | 0.020 | 0.007 |

| 1 (0.0730) | 0.0730 | 0.0695 | 0.118 | 0.112 | 0.073 | 0.070 | 0.005 | 0.072 | 1/161/16 | 0.0620.062 | 0.031 | 0.025 | 0.007 |

| 2 (0.0860) | 0.0860 | 0.0822 | 0.140 | 0.134 | 0.086 | 0.083 | 0.008 | 0.096 | 5/64 | 0.078 | 0.038 | 0.029 | 0.007 |

| 3 (0.0990) | 0.0990 | 0.0949 | 0.161 | 0.154 | 0.099 | 0.095 | 0.008 | 0.096 | 5/64 | 0.078 | 0.044 | 0.034 | 0.007 |

| 4 (0.1120) | 0.1120 | 0.1075 | 0.183 | 0.176 | 0.112 | 0.108 | 0.009 | 0.111 | 3/32 | 0.094 | 0.051 | 0.038 | 0.008 |

| 5 (0.1250) | 0.1250 | 0.1202 | 0.205 | 0.198 | 0.125 | 0.121 | 0.012 | 0.111 | 3/32 | 0.094 | 0.057 | 0.043 | 0.008 |

| 6 (0.380) | 0.1380 | 0.1329 | 0.226 | 0.218 | 0.138 | 0.134 | 0.013 | 0.133 | 7/64 | 0.109 | 0.064 | 0.047 | 0.008 |

| 8 (0.1640) | 0.1640 | 0.1585 | 0.270 | 0.262 | 0.164 | 0.159 | 0.014 | 0.168 | 9/64 | 0.141 | 0.077 | 0.056 | 0.008 |

| 10 (0.1900) | 0.1900 | 0.1840 | 0.312 | 0.303 | 0.190 | 0.185 | 0.018 | 0.183 | 5/32 | 0.156 | 0.090 | 0.065 | 0.008 |

| 1/4 (0.2500) | 0.2500 | 0.2435 | 0.375 | 0.365 | 0.250 | 0.244 | 0.025 | 0.216 | 3/16 | 0.188 | 0.120 | 0.095 | 0.010 |

| 5/16 (0.3125) | 0.3125 | 0.3053 | 0.469 | 0.457 | 0.312 | 0.306 | 0.033 | 0.291 | 1/4 | 0.250 | 0.151 | 0.119 | 0.010 |

| 3/8 (0.3750) | 0.3750 | 0.3678 | 0.562 | 0.550 | 0.375 | 0.368 | 0.040 | 0.372 | 5/16 | 0.312 | 0.182 | 0.143 | 0.010 |

| 7/16 (0.4375) | 0.4375 | 0.4294 | 0.656 | 0.642 | 0.438 | 0.430 | 0.047 | 0.454 | 3/8 | 0.375 | 0.213 | 0.166 | 0.015 |

| 1/2 (0.5000) | 0.5000 | 0.4919 | 0.750 | 0.735 | 0.500 | 0.492 | 0.055 | 0.454 | 3/8 | 0.375 | 0.245 | 0.190 | 0.015 |

| 5/8 (0.6250) | 0.6250 | 0.6163 | 0.938 | 0.921 | 0.625 | 0.616 | 0.070 | 0.595 | 1/2 | 0.500 | 0.307 | 0.238 | 0.015 |

| 3/4 (0.7500) | 0.7500 | 0.7406 | 1.125 | 1.107 | 0.750 | 0.740 | 0.085 | 0.620 | 5/8 | 0.625 | 0.370 | 0.285 | 0.015 |

| 7/8 (0.8750) | 0.8750 | 0.8647 | 1.312 | 1.293 | 0.875 | 0.864 | 0.100 | 0.698 | 3/4 | 0.750 | 0.432 | 0.333 | 0.020 |

| 1 (1.0000) | 1.0000 | 0.9886 | 1.500 | 1.479 | 1.000 | 0.988 | 0.114 | 0.790 | 3/4 | 0.750 | 0.495 | 0.380 | 0.020 |

| 1-1/8 (1.1250) | 1.1250 | 1.1086 | 1.688 | 1.665 | 1.125 | 1.111 | 0.129 | — | 7/8 | 0.875 | 0.557 | 0.428 | 0.020 |

| 1-1/4 (1.2500) | 1.2500 | 1.2336 | 1.875 | 1.852 | 1.250 | 1.236 | 0.144 | — | 7/8 | 0.875 | 0.620 | 0.475 | 0.020 |

| 1-3/8 (1.3750) | 1.3750 | 1.3568 | 2.062 | 2.038 | 1.375 | 1.360 | 0.160 | — | 1 | 1.000 | 0.682 | 0.523 | 0.020 |

| 1-1/2 (1.5000) | 1.5000 | 1.4818 | 2.250 | 2.224 | 1.500 | 1.485 | 0.176 | — | 1 | 1.000 | 0.745 | 0.570 | 0.020 |

| 1-3/4 (1.7500) | 1.7500 | 1.7295 | 2.625 | 2.597 | 1.750 | 1.734 | 0.207 | — | 1-1/4 | 1.250 | 0.870 | 0.665 | 0.020 |

| 2 (2.000) | 2.000 | 1.9780 | 3.000 | 2.970 | 2.000 | 1.983 | 0.238 | — | 1-1/2 | 1.500 | 0.995 | 0.760 | 0.020 |

| 2-1/4 (2.2500) | 2.2500 | 2.2280 | 3.375 | 3.344 | 2.250 | 2.232 | 0.269 | — | 1-3/4 | 1.750 | 1.120 | 0.855 | 0.036 |

| 2-1/2 (2.5000) | 2.5000 | 2.4762 | 3.750 | 3.717 | 2.500 | 2.481 | 0.300 | — | 1-3/4 | 1.750 | 1.245 | 0.950 | 0.036 |

| 2-3/4 (2.7500) | 2.7500 | 2.7262 | 4.125 | 4.090 | 2.750 | 2.730 | 0.332 | — | 2 | 2.000 | 1.370 | 1.045 | 0.036 |

| 3 (3.000) | 3.000 | 2.9762 | 4.500 | 4.464 | 3.000 | 3.979 | 0.363 | — | 2-1/4 | 2.250 | 1.495 | 1.140 | 0.036 |

| 3-1/4 (3.2500) | 3.2500 | 3.2262 | 4.875 | 4.837 | 3.250 | 3.228 | 0.394 | — | 2-1/4 | 2.250 | 1.620 | 1.235 | 0.036 |

| 3-1/2 (3.5000) | 3.5000 | 3.4762 | 5.250 | 5.211 | 3.500 | 3.478 | 0.426 | — | 2-3/4 | 2.750 | 1.745 | 1.330 | 0.036 |

| 3-3/4 (3.7500) | 3.7500 | 3.7262 | 5.625 | 5.584 | 3.750 | 3.727 | 0.458 | — | 2-3/4 | 2.750 | 1.870 | 1.425 | 0.036 |

| 4 (4.0000) | 4.0000 | 3.9762 | 6.000 | 5.958 | 4.000 | 3.976 | 0.489 | — | 3 | 3.000 | 1.995 | 1.520 | 0.036 |