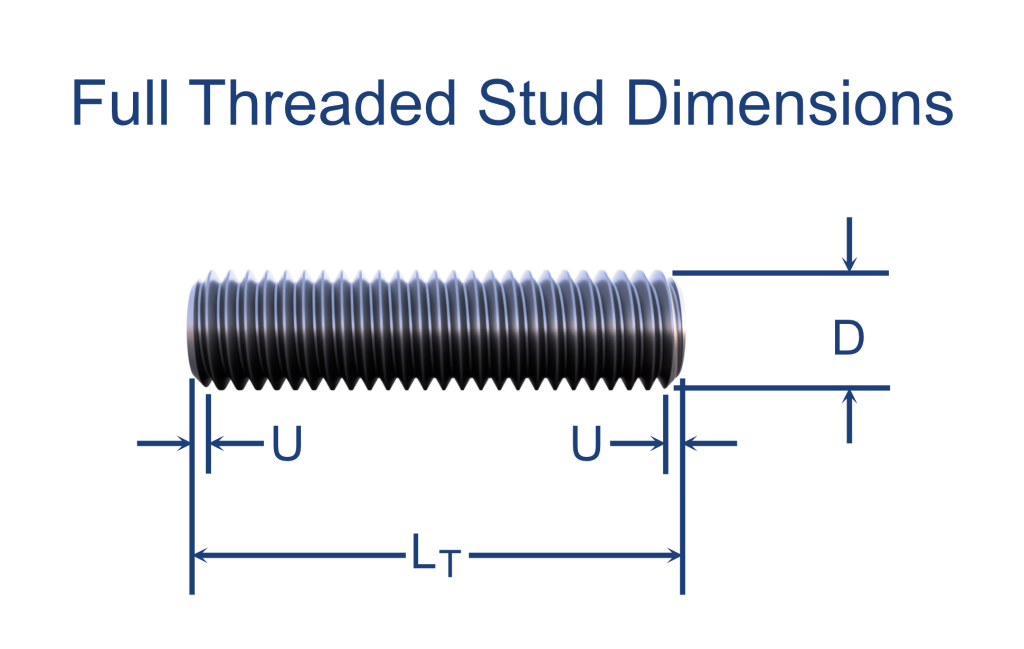

Dimensions

|

|||||||

| Nominal Size | Diameter, D | Threads Per Inch | Umax = 2 Thread Pitches = 2P | ||||

| UNC | UNF | 8UN | UNC Threads | UNF Threads | 8UN Threads | ||

| 1/4 | 0.2500 | 20 | 28 | — | 0.100 | 0.071 | — |

| 5/16 | 0.3125 | 18 | 24 | — | 0.111 | 0.083 | — |

| 3/8 | 0.3750 | 16 | 24 | — | 0.125 | 0.083 | — |

| 7/16 | 0.4375 | 14 | 20 | — | 0.143 | 0.100 | — |

| 1/2 | 0.5000 | 13 | 20 | — | 0.154 | 0.100 | — |

| 9/16 | 0.5625 | 12 | 18 | — | 0.167 | 0.111 | — |

| 5/8 | 0.6250 | 11 | 18 | — | 0.182 | 0.111 | — |

| 3/4 | 0.7500 | 10 | 16 | — | 0.200 | 0.125 | — |

| 7/8 | 0.8750 | 9 | 14 | — | 0.222 | 0.143 | — |

| 1 | 1.0000 | 8 | 12 | — | 0.250 | 0.167 | — |

| 1 1/8 | 1.1250 | 7 | 12 | 8 | 0.286 | 0.167 | 0.250 |

| 1 1/4 | 1.2500 | 7 | 12 | 8 | 0.286 | 0.167 | 0.250 |

| 1 3/8 | 1.3750 | 6 | 12 | 8 | 0.333 | 0.167 | 0.250 |

| 1 1/2 | 1.5000 | 6 | 12 | 8 | 0.333 | 0.167 | 0.250 |

| 1 5/8 | 1.6250 | — | — | 8 | — | — | 0.250 |

| 1 3/4 | 0.1750 | 5 | — | 8 | 0.400 | — | 0.250 |

| 1 7/8 | 1.8750 | — | — | 8 | — | — | 0.250 |

| 2 | 2.0000 | 4 1/2 | — | 8 | 0.444 | — | 0.250 |

| 2 1/4 | 2.2500 | 4 1/2 | — | 8 | 0.444 | — | 0.250 |

| 2 1/2 | 2.5000 | 4 | — | 8 | 0.500 | — | 0.250 |

| 2 3/4 | 2.7500 | 4 | — | 8 | 0.500 | — | 0.250 |

| 3 | 3.0000 | 4 | — | 8 | 0.500 | — | 0.250 |

| 3 1/4 | 3.2500 | 4 | — | 8 | 0.500 | — | 0.250 |

| 3 1/2 | 3.5000 | 4 | — | 8 | 0.500 | — | 0.250 |

| 3 3/4 | 3.7500 | 4 | — | 8 | 0.500 | — | 0.250 |

| 4 | 4.0000 | 4 | — | 8 | 0.500 | — | 0.250 |

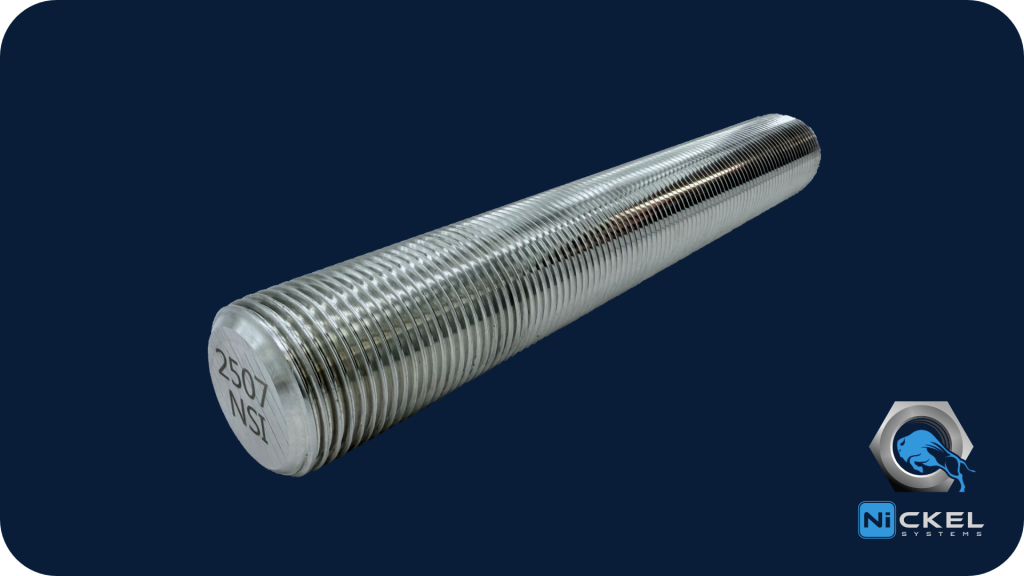

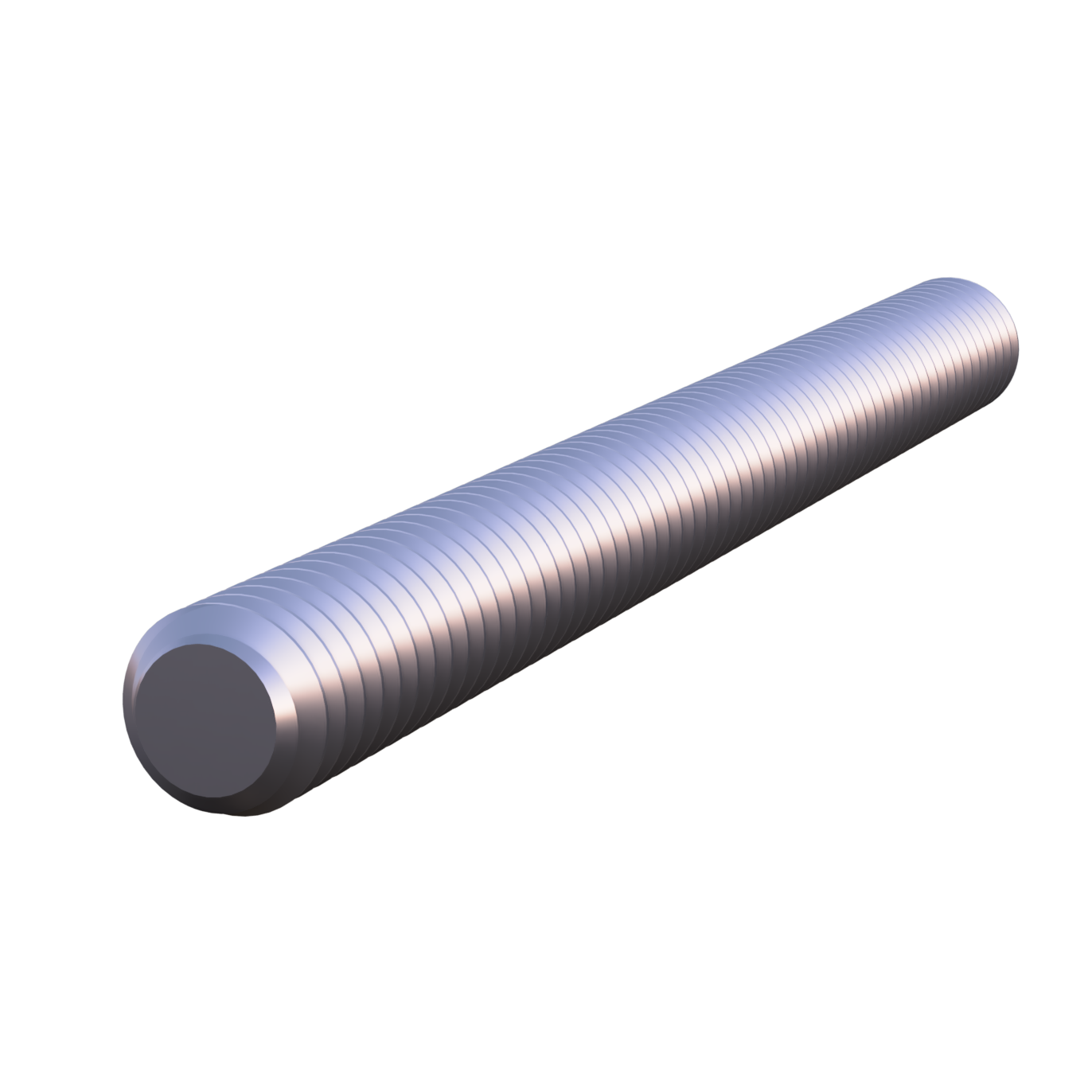

For common nominal sizes, full thread studs are typically stocked in 1/8″ increments up to 1″ long, in 1/4″ increments from 1″ to 6″ long & in 1/2″ increments from 6″ to 10″ long.