Specifications

- Plate, Sheet & Strip: ASTM B127, ASME SB127

- Rod, Bar, & Wire: ASTM B164, ASME SB164

- Forgings: ASTM B564, ASME SB564

Monel® was developed by the International Nickel Company in 1905, patented in 1906 and is now a trademark of Special Metals Corporation. Monel 400 (UNS N04400) is versatile and can resist corrosion in seawater applications. Monel alloy 405, a free-machining version of Monel alloy 400, shares the same physical and thermal properties but offers improved machinability.

Monel is made with precise computerized control in air induction furnaces instead of traditional direct ore smelting methods. Industries such as chemical and hydrocarbon processing leverage its extraordinary features to make fittings, boiler feeders and heat exchangers. It has a shiny surface with a distinct, slightly yellow color. This alloy is covered by standards ASTM B164, BS 3075, DTD 204B and 3076 NA 13.

Monel 400 is available from Nickel Systems in multiple forms for various industry applications.

If your question isn’t answered below, download the technical data sheet here.

These specifications and technical data are for Monel® 400. Monel® 400 is produced by and a trademark of Special Metals. If your project requires this specific material, you must request it at the time of quotation.

| Density | g/cm3 | 8.80 |

| lb/in3 | 0.318 | |

| Melting Range | °F | 2370-2460 |

| °C | 1300-1350 | |

| Modulus of Elasticity, 103 ksi | Tension | 26.0 |

| Compression | 26.0 | |

| Torsion | 9.5 | |

| Poisson’s Ratio | 0.32 | |

| Curie Temperature | °F | 70-120 |

| °C | 21-49 | |

| Temperature | Mean Linear Expansionb | Thermal Conductivitya | Specific Heata | Electrical Resistivitya,c | |||||

| °F | °C | in/in/°F x 10-6 | µm/m•°C | Btu-in/h/ft2/°F | W/m•°C | Btu/lb/°F | J/kg•°C | ohm-circ mil/ft | µΩ•m |

| -320 | -200 | – | – | – | – | – | – | 205 | .360 |

| -300 | -180 | 6.1 | 11.1 | 113 | 16.5 | 0.050 | 223 | – | – |

| -200 | -130 | 6.4 | 11.4 | 130 | 18.2 | 0.078 | 320 | – | – |

| -100 | -70 | 6.7 | 12.1 | 139 | 19.8 | 0.088 | 378 | – | – |

| 70 | 21 | – | – | 151 | 22.0 | 0.102 | 427 | 307 | 0.511 |

| 200 | 100 | 7.7 | 14.2 | 167 | 24.0 | 0.105 | 445 | 322 | 0.537 |

| 400 | 200 | 8.6 | 15.2 | 193 | 26.9 | 0.110 | 459 | 337 | 0.559 |

| 600 | 300 | 8.8 | 15.7 | 215 | 30.1 | 0.114 | 470 | 346 | 0.574 |

| 800 | 400 | 8.9 | 16.1 | 238 | 33.4 | – | – | 355 | 0.587 |

| 1000 | 500 | 9.1 | 16.3 | 264 | 36.5 | – | – | 367 | 0.603 |

| 1200 | 600 | 9.3 | 16.6 | 287 | 39.4 | – | – | 379 | 0.620 |

| 1400 | 700 | 9.6 | 17.0 | 311 | 42.4 | – | – | 391 | 0.639 |

| 1600 | 800 | 9.8 | 17.4 | 335d | 45.5d | – | – | 403 | 0.658 |

| 1800 | 900 | 10.0d | 17.7 | 360d | 48.8d | – | – | 415 | 0.675 |

| 2000 | 1000 | 10.3d | 18.1d | – | – | – | – | 427 | 0.692 |

aThese values also apply to MONEL alloy R-405, the free-machining version of MONEL alloy 400.

bAnnealed material. Between 70°F (21°C) and temperature shown.

cAnnealed material.

dExtrapolated.

| Form and Condition | Tensile Strength | Yield Strength (0.2% Offset) | Elongation, % | Hardness | |||

|---|---|---|---|---|---|---|---|

| Brinell (3000-kg) | Rockwell B | ||||||

| ksi | MPa | ksi | MPa | ||||

| Rod and Bar | |||||||

| Annealed | 75-90 | 517-620 | 25-50 | 172-345 | 60-35 | 110-149 | 60-80 |

| Hot-Finished (except Hexagons over 2 1/8 inches and Angles) | 80-110 | 552-758 | 40-100 | 276-690 | 60-30 | 140-241 | 75-100 |

| Hot-Finished Hexagons over 2 1/8 inches and Angles | 75-100 | 517-690 | 30-55 | 207-379 | 50-30 | 130-184 | 72-90 |

| Cold-Drawn, Stress-Relieved | 84-120 | 579-827 | 55-100 | 379-690 | 40-22 | 160-225 | 85-20C |

| Plate | |||||||

| Hot-Rolled, As-Rolled | 75-95 | 517-655 | 40-75 | 276-517 | 45-30 | 125-215 | 70-96 |

| Hot-Rolled, Annealed | 70-85 | 482-586 | 28-50 | 193-345 | 50-35 | 110-140 | 60-76 |

| Sheet | |||||||

| Annealed | 70-85 | 482-586 | 30-45 | 207-310 | 45-35 | – | 65-80 |

| Cold-Rolled, Hard | 100-120 | 690-827 | 90-110 | 621-758 | 15-2 | – | 93 min.a |

| Strip, Cold-Rolled | |||||||

| Annealed | 70-85 | 482-586 | 25-45 | 172-310 | 55-35 | – | 68 max.a |

| Spring Temper | 100-140 | 690-965 | 90-130 | 621-896 | 15-2 | – | 98 min.a |

| Tube and Pipe, Seamless | |||||||

| Cold-Drawn, Annealed | 70-85 | 482-586 | 25-45 | 172-310 | 50-35 | – | 75 max.a |

| Cold-Drawn, Stress-Relieved | 85-120 | 586-827 | 55-100 | 379-690 | 35-15 | – | 85-100a |

| Heat-Exchanger, Annealed | 70-85 | 482-586 | 28-45 | 193-310 | 50-35 | – | 75 max.a |

| Heat-Exchanger, Stress-Relieved | 85-105 | 586-724 | 55-90 | 379-621 | 35-15 | – | 85-97a |

| Hot-Extruded | -b | -b | -b | -b | -b | – | -b |

| No. 1 Temper (Annealed) | 85 max. | 586 max. | 30-45 | 207-310 | 45-30 | – | 73 max.a |

| No. 2 Temper (Half-Hard) | 85-105 | 586-724 | 55-80 | 379-552 | 30-10 | – | 75-97a |

| No. 3 Temper (Full-Hard) | 110-130 | 758-896 | 90-110 | 621-758 | 10-3 | – | 95-27C |

| Wire, Cold Drawnc | |||||||

| Annealed | 70-95 | 482-655 | 30-55 | 207-379 | 45-25 | – | – |

| No. 1 Temper | 85-100 | 586-690 | 50-75 | 345-517 | 30-20 | – | – |

| Quarter-Hard | 95-120 | 655-827 | 65-95 | 448-655 | 25-15 | – | – |

| Half-Hard | 110-135 | 758-931 | 85-120 | 586-827 | 15-8 | – | – |

| Three-Quarter-Hard | 125-150 | 862-1034 | 100-135 | 690-931 | 8-5 | – | – |

| Full-Hard–Spring Temper | 145-180 | 1000-1241 | 125-170 | 862-1172 | 5-2 | – | – |

a The ranges shown are composites for various product sizes and therefore are not suitable for specification purposes. Hardness values are suitable for specification purposes providing tensile properties are not also specified.

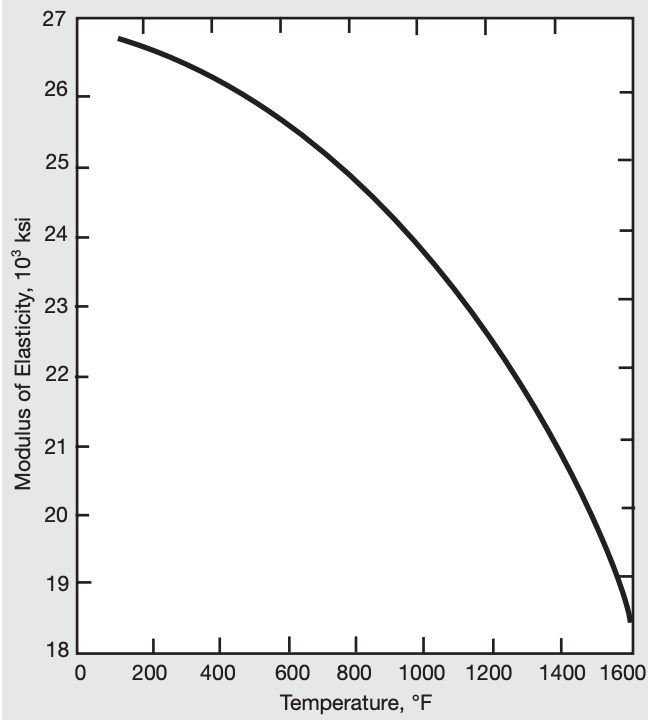

b Properties on request.Effect of temperature on modulus of elasticity in tension of MONEL alloy 400 (determined by dynamic method).

c Properties shown are for sizes from 0.032 to 0.250-in. diameter. Properties for other sizes may vary from these.

| Temper | Rockwell B Hardness | |

|---|---|---|

| Sheet | Strip | |

| Deep-Drawing and Spinning Quality | 76 max. | 76 max. |

| Annealeda | 73 max. | 68 max. |

| Skin-Hard | – | 68-73 |

| Quarter-Hard | 73-83 | 73-83 |

| Half-Hard | 82-90 | 82-90 |

| Three-Quarter-Hard | – | 89-94 |

| Hard | 93 min. | 93-98 |

| Spring | – | 98 min. |

| Hot-rolled and cold-drawn rods and forgings

|

Sheet and strip

|

| Temper | Temperature, °F | Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Elongation, % | Reduction of Area, % |

|---|---|---|---|---|---|

| Cold-Drawn | Room | 103.80 | 93.70 | 19.0 | 71.0 |

| -110 | 117.45 | 100.85 | 21.8 | 70.2 | |

| Rooma | 103.40 | 93.30 | 17.3 | 72.5 | |

| Forged | 70 | 92.00 | 67.00 | 31.0 | 72.7 |

| -297 | 128.25 | 91.50 | 44.5 | 71.8 | |

| -423 | 142.00 | 96.40 | 38.5 | 61.0 | |

| Annealed | 70 | 78.65 | 31.30 | 51.5 | 75.0 |

| -297 | 115.25 | 49.50 | 49.5 | 73.9 |

aHeld at -110°F for several hours prior to testing at room temperature.

| Form and Condition | Dia., in. | Tensile Properties | Torsional Properties | Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Breaking Strength, ksi | Proportional Limit, ksi | Breaking Strength Torsional/ Tensile Strength | Torsional Proportional Limit/ Tensile Strength | Torsional Proportional Limit/ Torsional Breaking Strength | ||

| Wire | ||||||||

| Cold-Drawn, 75% | 0.148 | 157 | – | 110 | 68 | 0.700 | 0.433 | 0.618 |

| Cold-Drawn, 75% Stress-Relieved |

0.148 | 160 | – | 105 | 65 | 0.656 | 0.404 | 0.619 |

| Rod | ||||||||

| Hot-Rolled | 1 | 86 | 38 | 66 | 23 | 0.768 | 0.267 | 0.349 |

| Cold-Drawn, 20% | 1 | 115 | 107 | 72 | 47 | 0.626 | 0.408 | 0.653 |

| 1.5 | 113 | 102 | 71 | 45 | 0.628 | 0.398 | 0.634 | |

| Temper | Compression | Tension | ||||

|---|---|---|---|---|---|---|

| Yield Strength (0.01% Offset), ksi | Yield Strength (0.2% Offset), ksi | Tensile Strength, ksi | Yield Strength (0.01% Offset), ksi | Yield Strength (0.2% Offset), ksi | Elongation, % | |

| Hot-Rolled | 33 | 38 | 84 | 37 | 41 | 39.5 |

| Cold-Drawna | 58 | 81 | 97 | 75 | 87 | 27.0 |

| Annealedb | 19 | 28 | 78 | 28 | 33 | 44.0 |

a Stress-equalized at 525°F after cold drawing.

b Cold-drawn +1450°F/3 hr, F.C.

| Temper | Thickness, in. | Shear Strength, ksi | Tensile Strength, ksi | Hardness, Rb | Ratio Shear Strength/Tensile Strength |

|---|---|---|---|---|---|

| Hot-Rolled, Annealed | 0.042 | 48.75 | 73.0 | 65 | 0.67 |

| Cold-Rolled, Annealed | 0.029 | 49.50 | 76.8 | 60 | 0.65 |

a Double-shear tests at room temperature.

| Property | Condition | |

| Annealed | B & S No. 1a | |

| Shear Strength, ksi | ||

| Room Temp | 48.5 | 54.5 |

| 600b | 45.0 | 52.0 |

| 800b | 37.0 | 47.5 |

| 1000b | 29.0 | 38.0 |

| 800c | 38.5 | 49.5 |

| 1000c | 30.5 | 38.5 |

| Tensile Strength, ksi | 78.5 | 88.0 |

| Yield Strength (0.2% Offset), ksi | 46.0 | 75.5 |

| Elongation, % | 41 | 18 |

aCorresponds to the approximate strength of the shank of a headed rivet. b30 min at temperature before testing. c24 hr at temperature before testing.

| Temperature, °F | Maximum Load, lb | Corrected Energy Values, ft-lb | Reduction in Thickness, % | ||

| Initiation | Propagation | Total | |||

| Room | 32,340 | 715 | 2008 | 2723 | 57.0 |

| -184 | 39,000 | 649 | 2402 | 3051 | 50.0 |

| -238 | 42,000 | 795 | 2408 | 3203 | 51.0 |

| -320 | 47,800 | 899 | 2802 | 3701 | 46.0 |

| -320b | 41,300 | 676 | 2138 | 2814 | 45.0 |

aIn all cases, appearance of fracture was double-cup shear. bTested with jeweler’s-saw notch

| Temper | Tensile Properties | Bearing Strength | Ratio, Bearing Strength/ | ||||

| Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Elongation, % | Yield Strengtha, ksi | Ultimate Strengthb, ksi | Yield Strength | Ultimate Strength | |

| Annealed | 70.0 | 27.2 | 42.5 | 58.0 | 145.0 | 2.13 | 2.07 |

| Half-Hard | 75.8 | 56.2 | 32.0 | 98.1 | 166.0 | 1.75 | 2.19 |

| Full-Hard | 117.8 | 110.0 | 5.0 | 162.0 | 211.5 | 1.47 | 1.79 |

a2% enlargement of hole diameter in sheet. bTearing out of sheet.

| Temper | Impact Strength, ft•lb | |

| Izod | Charpy U Notch | |

| Hot-Rolled | 100-120+ | 220 |

| Forged | 75-115 | — |

| Cold-Drawn | 75-115 | 150 |

| Annealed | 90-120+ | 215 |

a Tested at room temperature. None of the specimens was completely fractured.

| Temper | Tensile Impact | Tensile Properties | ||||||

| Impact Strength, ft•lb | Elongation in 3.54″, % | Reduction of Area, % | Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Elongation in 2″, % | Reduction of Area, % | Hardness, Brinell (3000-kg) | |

| Cold Drawn 24% Stress Relieved | 96a | 15.0 | 63.7 | 97.25 | 86.65 | 27.0 | 66.4 | 199 |

| Annealed 1450°F/ 3 hr | 129a | 29.5 | 68.0 | 78.35 | 33.35 | 44.0 | 65.9 | 123 |

aSpecimen completely broken.

| Temper | Impact Strength | Angle of Twista, Degree | Hardness, Brinell (3000-kg) | |

| ft•lb | ft•lb/in2 | |||

| Hot-Rolled | 34 | 694 | 101.5 | 145 |

| Cold-Drawn 24%, Stress-Relieved | 39 | 788 | 98.0 | 199 |

| Annealed 1450°F/3 hr | 30 | 599 | 102.0 | 123 |

aGage length about 3/16 in.

| Temper | Impact Strength, ft•lb | |||

| 75°F | -20°F | -112°F | -310°F | |

| Hot-Rolled | 219 | — | 213 | 196 |

| Cold-Drawn, Annealed | 216 | 212 | 219 | 212 |

| Weld, As-Welded | 78 | — | — | 73 |

| Temperature, °F | Notch | Orientation | Impact Strength, ft•lb |

| -423a | V | Long. | 141-219 |

| -423a | V | Trans. | 121-216 |

| -423a | Keyhole | Long. | 81-87 |

| -423a | Keyhole | Trans. | 72-75 |

| -440b | V | Long. | Unbroken |

| -440b | V | Trans. | 171-193 |

| -440b | Keyhole | Long. | 123-146 |

| -440b | Keyhole | Trans. | 91-116 |

aRange for 5 tests liquid-hydrogen temperature. bRange for 4 tests at liquid-helium temperature.

Fatigue Strengtha of MONEL Alloy 400 Rod

| Temper | Fatigue Strength (108 cycles), ksi | Tensile Strength, ksi | Ratio Fatigue Strength/ Tensile Strength |

| Annealed | 33.5 | 82.0 | 0.41 |

| Hot-Rolled | 42.0 | 88.0 | 0.48 |

| Cold-Drawn, As-Drawn | 40.5 | 105.0 | 0.39 |

| Cold-Drawn, Stress-Equalizedb | 44.0 | 104.0 | 0.42 |

| Cold-Drawn, Stress-Relievedc | 37.0 | 96.5 | 0.38 |

aRotating-beam tests of polished specimens in air at room temperature and 10,000 rpm. b525°F/3 hr. c1000°F/3 hr.

| Temper | Fatigue Strength (108 cycles), ksi | Tensile Strength, ksi | Ratio Fatigue Strength/ Tensile Strength |

| Annealed | 21.0 | 74.7 | 0.28 |

| Quarter-Hard | 24.5 | 76.5 | 0.32 |

| Half-Hard | 28.5 | 84.2 | 0.34 |

| Full-Hard | 39.0 | 126.0 | 0.31 |

| Full-Hard, Stress-Equalized (525°F/21 hr) | 41.0 | 133.0 | 0.31 |

aAs-rolled surface. Tested in air at room temperature. Specimen length parallel to direction of rolling. Completely reversed stress.

| Wire (0.0375-in. diameter, cold-drawn 75% after final anneal)

Tested in processed condition. Data determined with a rotatingwire (5000 rpm) arc-fatigue machine. |

Rod (0.500-in. diameter, cold-drawn, annealed 1500°F/3 hrs)

Tested in the processed condition. Data determined by the R.R. Moore rotating beam technique. |

| Cold-drawn annealed (1500°F/3 hr)

|

20% Cold-drawn Stress-relieved (1000°F/8 hr)

|

| Cold-drawn annealed (1500°F/30 min)

|

Cold-drawn, Stress-relieved (1100°F/8 hr)

|

| Cold-drawn rod

|

Hot-rolled Plate (Hardness converted from BHN.)

|

| Temperature, °F | Tensile Strength, ksi | Yield Strength (0.2% Offset), ksi | Elongation, % | Reduction of Area, % |

|---|---|---|---|---|

| All-Weld Metal | ||||

| Room | 74.35 | 46.65 | 41.0 | 66.4 |

| 200 | 42.25 | 46.05 | 39.0 | 56.5 |

| 400 | 68.60 | 43.10 | 33.5 | 64.2 |

| 600 | 69.25 | 43.15 | 34.0 | 59.9 |

| 800 | 66.10 | 43.00 | 32.5 | 47.4 |

| 1000 | 55.95 | 38.70 | 22.0 | 24.5 |

| Transverse Across Weldb | ||||

| Room | 76.2 | 48.50 | 24.0 | 48.0 |

| 400 | 69.6 | 45.00 | 24.0 | 58.3 |

| 600 | 68.5 | 45.80 | 21.0 | 56.5 |

| 800 | 69.0 | 41.00 | 28.0 | 44.2 |

aButt joints–1/2-in. MONEL alloy 400. bAll breaks occurred in weld.

| Property | As-Welded | Heat-Treated 1150°F/10 hr, A.C. | ||

| All-Weld Metal | Transverse Across Welda | All-Weld Metal | Transverse Across Welda | |

| Tensile Strength, ksi | 71.0 | 78.0 | 70.5 | 76.4 |

| Yield Strength, ksi | 48.3 | 51.5 | 45.3 | 36.7 |

| Elongation, % | 38 | 21 | 38 | 31 |

| Reduction of Area, % | 63.3 | 60.5 | 63.3 | 59.3 |

aBreak occurred in weld.

This solid-solution nickel-copper alloy exhibits high strength and toughness over a wide temperature range. It is resistant to steam, seawater, and highly caustic solutions such as sulfuric, hydrofluoric, and hydrochloric acids. This material has excellent weldability and can withstand immense pressure and weight.

Monel 400 composition includes a minimum of 63% nickel and up to 34% copper. Monel 400 exhibits a density of approximately 8.80 g/cm³ (0.318 lb/in³) and a melting range of 1,300-1,350°C (2,370-2,460°F). Its elastic modulus in tension is about 26.0 ksi (26,000 psi), reflecting its ability to withstand corrosion.

It has excellent mechanical properties at extremely cold temperatures. Compared to other alloys like stainless steel, Monel 400 has excellent ductility, durability, machinability and corrosion resistance.

Monel 400 fasteners are highly valued for their exceptional corrosion resistance, making them ideal for harsh environments. Their unique properties and composition have several advantages for various use cases:

Monel 400 fasteners are commonly used in industries that require high corrosion resistance and mechanical strength. This alloy excels in aerospace, chemical plant equipment, marine engineering, nuclear power plants, mining and oil and gas. Applications include:

Monel 400 is available in a variety of fasteners, including:

The combination of excellent resistance at high temperatures and excellent corrosion resistance makes the Monel alloy a great selection for various applications. Selecting the appropriate fastener for specific applications depends on these factors:

Fasteners made from this alloy are an excellent choice for various applications due to their unique properties. When selecting the appropriate fastener, consider the following factors:

Monel 400 fasteners offer a balance between high performance and cost efficiency. While they are more expensive than standard materials like stainless steel, their superior durability and corrosion resistance lead to reduced maintenance and replacement needs when paired with similar metals. Compared to premium alloys like Monel K-500 or Inconel®, Monel 400 is a more economical choice for applications where extreme strength or high-temperature resistance is not the primary requirement.

Consulting with experts can provide tailored recommendations based on your application needs, ensuring you select the most suitable fastener for optimal performance and longevity.

Check out our sample products for Monel® 400: