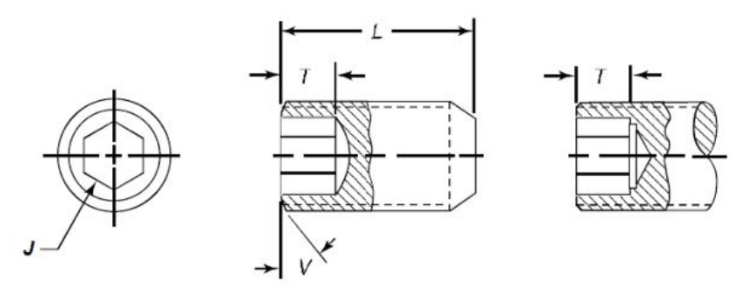

Cold Formed Socket Set Screws

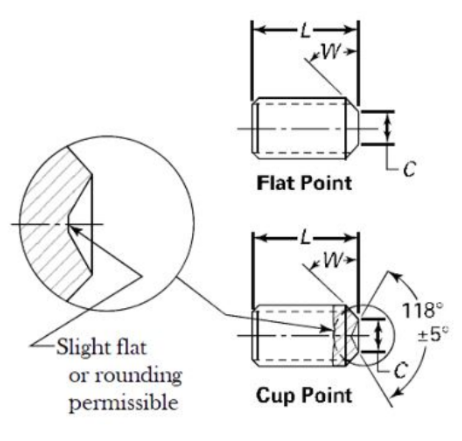

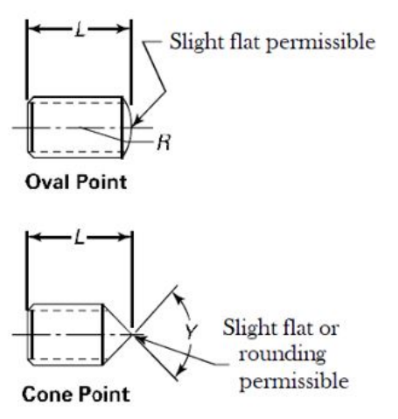

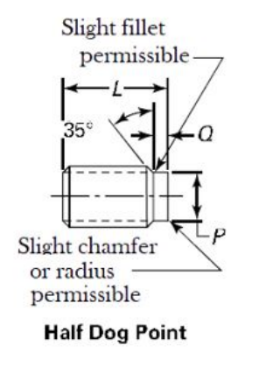

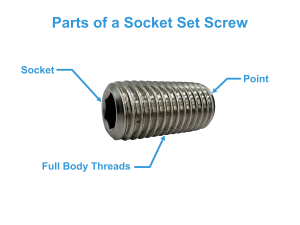

Cold-formed socket set screws are specialized fasteners designed for secure, adjustable connections in various mechanical and structural applications. Manufactured using a cold-forming process, these screws are shaped at room temperature, enhancing their material strength and dimensional precision. Made from materials such as alloy steel or stainless steel, cold-formed socket set screws are commonly employed in industries like automotive, aerospace, and machinery manufacturing, where reliability and precision are essential. Nickel Systems offers a wide range of cold formed socket set screws in materials such as 410 stainless steel, Alloy 20, Brass or other alloy steel. We also stock various points including cup point, flat point, dog point, & knurled point set screws. Ask us about our domestic, cold forming, ASME 18.3-2012 cold formed inventory.

REQUEST A QUOTE