What Are Washers?

Washers are thin, disc-shaped components with a central hole that fits over a bolt or screw shaft. Their primary function is distributing the load from the fastener’s head or nut over a wider surface area, protecting the underlying material and reducing the risk of damage or deformation.

Common Types

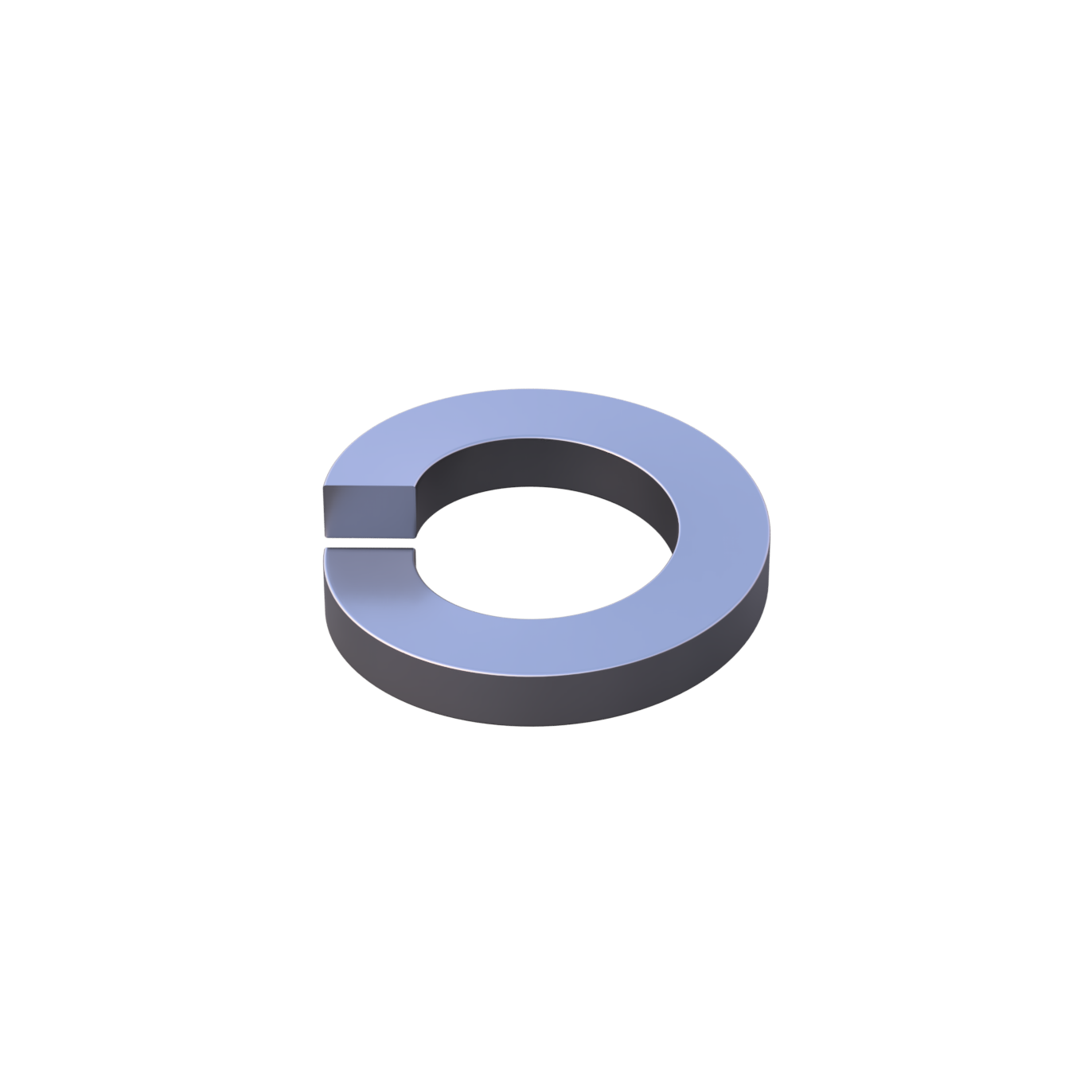

What Are Lock Washers?

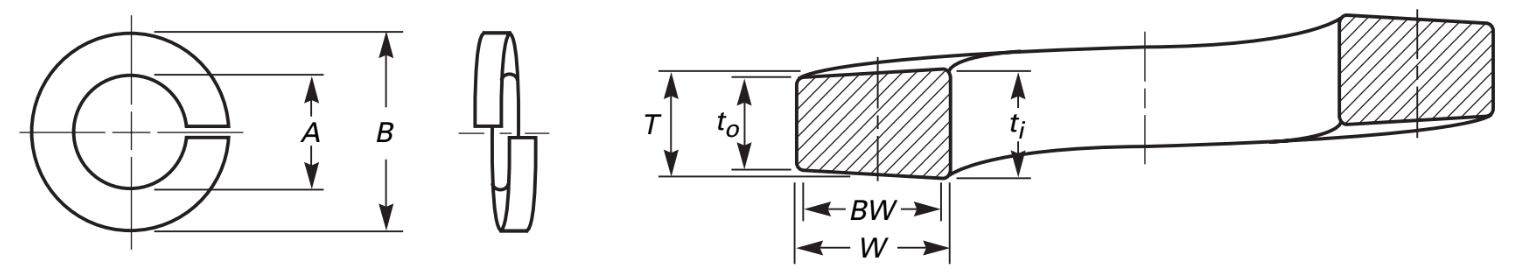

Lock washers are a specialized category of washers that resist rotational loosening. Unlike flat washers, they apply elastic tension that resists movement, making them indispensable in dynamic assemblies subject to vibration or stress. Their coiled or split design engages with the fastener and substrate, creating a mechanical hold. Lock washers are ideal in environments where conventional nut-bolt combinations may loosen over time due to cyclical loads or temperature variation.

Split lock washers are made mostly from coils of wire. Lock washers made from coil are subject to high-volume production runs. Steel and stainless steel lock washers become work hardened in the manufacturing process and possess more strength and spring than the raw material.

Lock washers made from nickel-based alloys and stainless, other than 18-8 or 316, are generally machined from plate stock. There is not enough demand to make these parts from coil. Washers made from plate are not as strong as those made from coil and cannot be reused. Nickel Systems maintains an inventory of split lock washers, and we can re-machine specific sizes to produce hi-collar lock washers for use with socket-head cap screws.

Other Names Used for This Product

Lock washers are also known as:

- Split washers

- Spring washers

- Locking washers

- Helical lock washers

Industries and Applications

Lock washers provide mechanical stability across various demanding industries.

Aerospace

Lock washers ensure critical aerospace components remain secure despite extreme vibrations and thermal fluctuations.

- Applications: Engine mounts, avionics enclosures, structural assemblies

- Materials: Inconel®, Hastelloy®, Titanium alloys, Alloy A286

Automotive

In automotive settings, lock washers enhance the durability and performance of components subject to frequent vibration and mechanical stress.

- Applications: Suspension systems, drivetrain components, engine mounts

- Materials: Stainless steel, aluminum alloys

Manufacturing

Lock washers support the reliable operation of heavy-duty manufacturing equipment, maintaining structural integrity under repetitive stress conditions.

- Applications: Heavy machinery assemblies, conveyor systems, presses

- Materials: Alloy A286, Carpenter® 20, Inconel®, Haynes® 242

Tips for Purchasing Lock Washers

When selecting lock washers for your project, consider the following purchasing guidelines to help identify the correct product for your environment and mechanical conditions:

- Match material to conditions: Select materials with chemical, temperature and corrosion resistance suited to your environment.

- Verify dimensions: Confirm that the washer’s thickness and inner and outer diameters match your bolt and assembly requirements.

- Account for reusability: Lock washers are typically single-use components, so plan replacements accordingly in systems with regular maintenance.

- Explore custom options: Specify finishes, coatings or custom configurations suited to your application requirements.

- Consider load and vibration: Assess the washer’s compatibility with the intended application’s torque and vibration levels.